Glass-ceramics for joining Al2O3f/Al2O3-ZrO2 composites exposed to direct flame

By Carla Malinverni (POLITO – Politecnico di Torino)

Another joining success from our project partner Politecnico di Torino. Discover the innovative research focused on advancing the joining processes of oxide/oxide ceramic matrix composites (CMCs) for assembling radiant tube components used in the steelmaking industry in the framework of the CEM-WAVE Project.

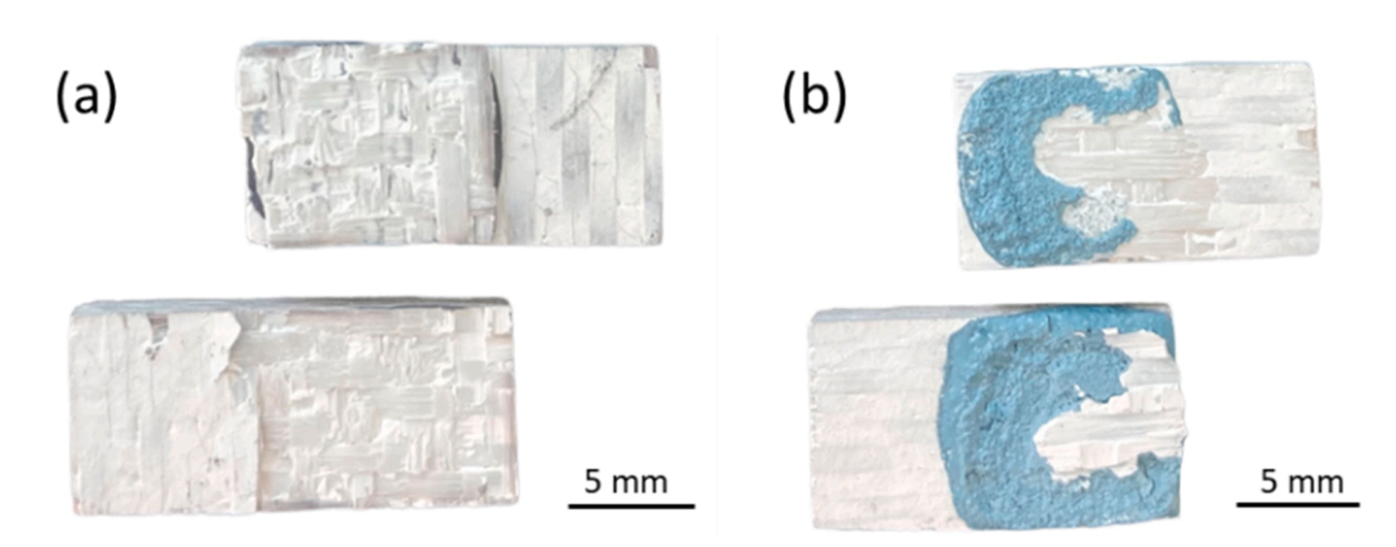

Ceramic matrix composites are designed to perform in extremely harsh environments, where they must resist high temperatures, corrosion, and combustion. Oxide/oxide CMCs are selected thanks to their unique high-performance properties, such as intrinsic oxidation resistance. The composites used in this work were composed of an alumina-zirconia matrix reinforced with Nextel™ 610 alumina fibers. This study introduced two glass-ceramic systems, named T1 and T2M, with the peculiarity of having Y2Ti2O7 as their primary crystalline phase, and with an optimized chemical composition to fulfill the criteria of wettability, thermomechanical compatibility, and matching of the coefficient of thermal expansion with the composite substrate. These two glass-ceramic systems were used as joining materials, and they showed excellent performance under harsh operating conditions to simulate the in-service environment such as direct flame exposure and thermal cycling. In particular, the findings suggested that T1 glass-ceramic is particularly suitable for joining oxide/oxide CMCs in high-temperature applications. These novel joining materials showed great adhesion to the composite, confirmed through mechanical shear testing (Figure 1) which resulted in the delamination of the oxide/oxide composite, and in-service conditions using direct flame exposure testing.

Fracture surfaces of T1 (a) and T2M (b) oxide/oxide joints after single lap offset mechanical tests.

Exposed directly to 900°C flames and subjected to thermal cycling between 400°C and 900°C, the glass-ceramic joints demonstrated exceptional durability and reliability. This development represents a major leap forward in materials technology for the joining of oxide/oxide ceramic matrix composites, as well as improving the performance and longevity of radiant tube components.

This research was conducted by the CEM-WAVE partner Politecnico di Torino (POLITO) (Work Package 6 Leader), at the Department of Applied Science and Technology (DISAT) and the J-Tech - Advanced Joining Technology research center at Politecnico di Torino, together with the University of Bayreuth, Germany, which supplied the oxide/oxide ceramic matrix composites, and the project partner University Bourgogne Franche-Comtè, ICB-CNRS, Belfort, France, that performed the flame exposure tests.

A scientific paper was published in the Journal of the European Ceramic Society, and can be found at the link https://doi.org/10.1016/j.jeurceramsoc.2023.02.019

Or access to our CEM-WAVE Zenodo community : https://zenodo.org/records/7696500

Publication on JECS.