The Life Cycle Analysis, a great tool for a greener future

A popular methodology based on internationally recognised standards, the CEM-WAVE project uses Life Cycle Analysis (LCA) to measure environmental impact and foster green manufacturing

By Shahin Sayyareh (Steinbeis Advanced Risk Technologies, R-Tech)

In December 2019, the European Commission presented the “The European Green Deal”, and defined it as “a roadmap for making the EU's economy sustainable by turning climate and environmental challenges into opportunities across all policy areas and making the transition just and inclusive for all”. The Deal promised an unprecedented impact on the economy of the European Union (EU) and the implementation of its financed Research and Development projects, such as CEM-WAVE.

Even though the “eco-design approach” and its benefits for the environment emerged decades ago since the introduction of the Green Deal industrial and academic organizations all around Europe have started to pay special attention to justify how their activities align with the newly announced regulations. This means they have been optimizing service and product supply chains to minimize their environmental impact. In broader terms, the EU Green Deal targets the 17 Sustainable Development Objectives (SDGs) adopted by the United Nations in 2015, highlighting the economic and social aspects of sustainable development.

To proactively address these overarching goals, and make sure organizational activities comply with the Green Deal ideals, companies need tools and methodologies to measure their performance. For example, a preliminary assessment must be carried out at the earliest stages of product and service design, when most of the decisions are made, and the different characteristics of the product/service are determined.

The “Life Cycle Analysis” or “LCA” is a methodology that assists organizations in evaluating their environmental performance. The LCA is certified by the International Standardisation Organisation (ISO), and benefits from the standardised guidelines provided by ISO 14040 and ISO 14044. Furthermore, it considers the entire product life cycle, from the extraction of raw materials to the stage when a product is no longer usable and must be disposed of, namely the “End-of-Life” stage. Figure 1 below demonstrates the LCA framework as described within the ISO 14040.

A software programme, which defines the material and energy flows involved in the product life cycle, is usually used to streamline the LCA methodology. By inserting unit process values as input and output values of each process within the production system, the LCA software calculates the environmental impacts based on the given data and the information that already exists in its database. In other words, based on the provided values, the software recalls similar processes as a reference unit from its database and scales them up to calculate the environmental impact. LCA databases contain a large amount of data collected from SMEs and manufacturers in different industrial fields.

In addition, there are other impact assessment or Life Cycle Impact Assessment (LCIA) methodologies available to run calculations in LCA programmes. Depending on the chosen LCIA method, different impact categories such as Global Warming Potential (GWP), Human Toxicity, Ozone Layer Depletion, etc., can be assessed to obtain LCA results. It is advisable that the LCA practitioner possesses a fundamental knowledge of Environmental Sciences or, preferably, Process Engineering, for her or him to have a sufficient understanding of the LCA analysis processes and results.

How is the LCA used in CEM-WAVE?

First, CEM-WAVE is a scientific research and development project, which deals with innovative materials. Therefore, at least at the primary stages, its investigated production processes are usually operated at a laboratory scale, and no sufficient or precise data is available for them within the LCA databases. For the CEM-WAVE and other similar projects, Steinbeis R-Tech introduced the “Innovation Oriented LCA Analysis”, which integrates the LCA with the methodologies that are not solely dependent on numerical data, such as the Risk Assessment Methodology. Although the Risk Assessment investigates various categories of risks, it does point out the processes with the highest potential environmental risks, the so-called “hotspots”. In addition, in CEM-WAVE the LCA is used to facilitate process modelling at an early project stage when it mainly aims at estimating the impacts from energy consumptions rather than those from material flows.

In practice, we can summarise the strategy used for CEM-WAVE’s LCA and Impact Assessment in five steps:

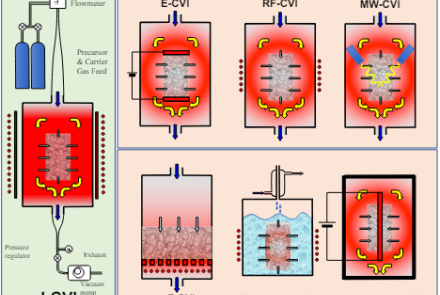

- We defined the aim and scope of the analysis at two different levels. First, we perform a Mid-term LCA that addresses the Microwave-assisted Chemical Vapour Infiltration (MW-CVI) process to produce oxide and non-oxide Ceramic Matrix Composites (CMCs) materials. Second, we perform an overall LCA on the final products.

- We designed an Excel template and shared it with all consortium members to facilitate data collection related to their processes. This helps us to have a unified set of numerical values for all the processes within the project.

- Using the collected data, we mapped each unit process and drew a flow diagram to discuss with the relevant partners and ensure the reliability of both the data and flow diagrams.

- After each partner approves the flow diagrams and numerical values, we can transfer the information to the LCA software programme. With the programme, we model the processes in terms of material/energy flows and calculate their environmental impact. For the CEM-WAVE project, we use the Sphera GaBi software. Figure 2 below shows an example of a flow diagram modelled in GaBi.

- Finally, we report and interpret the quantitative values to discuss the overall environmental performance of the project and its final products.

According to the LCA framework, we call the first step in the above-mentioned workflow Goal and Scope Definition. Steps 2 and 3 correspond to Inventory Analysis and step 4 addresses the Impact Assessment. Step 5, where results are reported and interpreted, covers the Interpretation stage.

Last but not least, one of the main success factors in a good LCA – in general, and also in the CEM-WAVE project – is data. Hence, the LCA practitioner involved in a complex project analysis must communicate with the other partners regularly to ensure that they submit the data on time and the analysis covers all the necessary processes.

This is just a summary of what we are trying to achieve at Steinbeis R-Tech with the help of all project partners and using different tools, such as the shared Excel file and regular meetings. Continue to follow us for more news on our assessment of how the CEM-WAVE project can spearhead greener technology in ceramic and steel production!